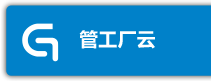

[talk about the machine via camera] Perfect combination of high efficiency and high precision with outstanding stability–CFV1100Ⅱ High-speed Vertical Machining Center

2023-11-30

The new CFVⅡ high-speed vertical machining center inherit the excellent performance of its predecessor and further expands the features of high efficiency, high precision, and high reliability. Each component has been subject to a number of functional upgrades and optimized design. In line with an ergonomic layout, it enhances the operating experience. This series is suitable for all types of processing in the parts and mold market. Let’s follow the camera to explore!

Features:

01 Optimize the component structure

Highly rigid foundation components, large-span thickened bed base and bottom closed column. Lightweight moving parts, with the total weight of the headstock and motor spindle 30% less than the norm.

02 High-speed and high-precision built-in motor spindle

Built-in motor direct drive with no other vibration source. Star-delta switching two-speed automatic transmission, low-speed high torque, high-speed constant power. “Zero” transmission, small inertia, stator with instantaneous high power output, 0 to 8000 rpm start in 0.8s.

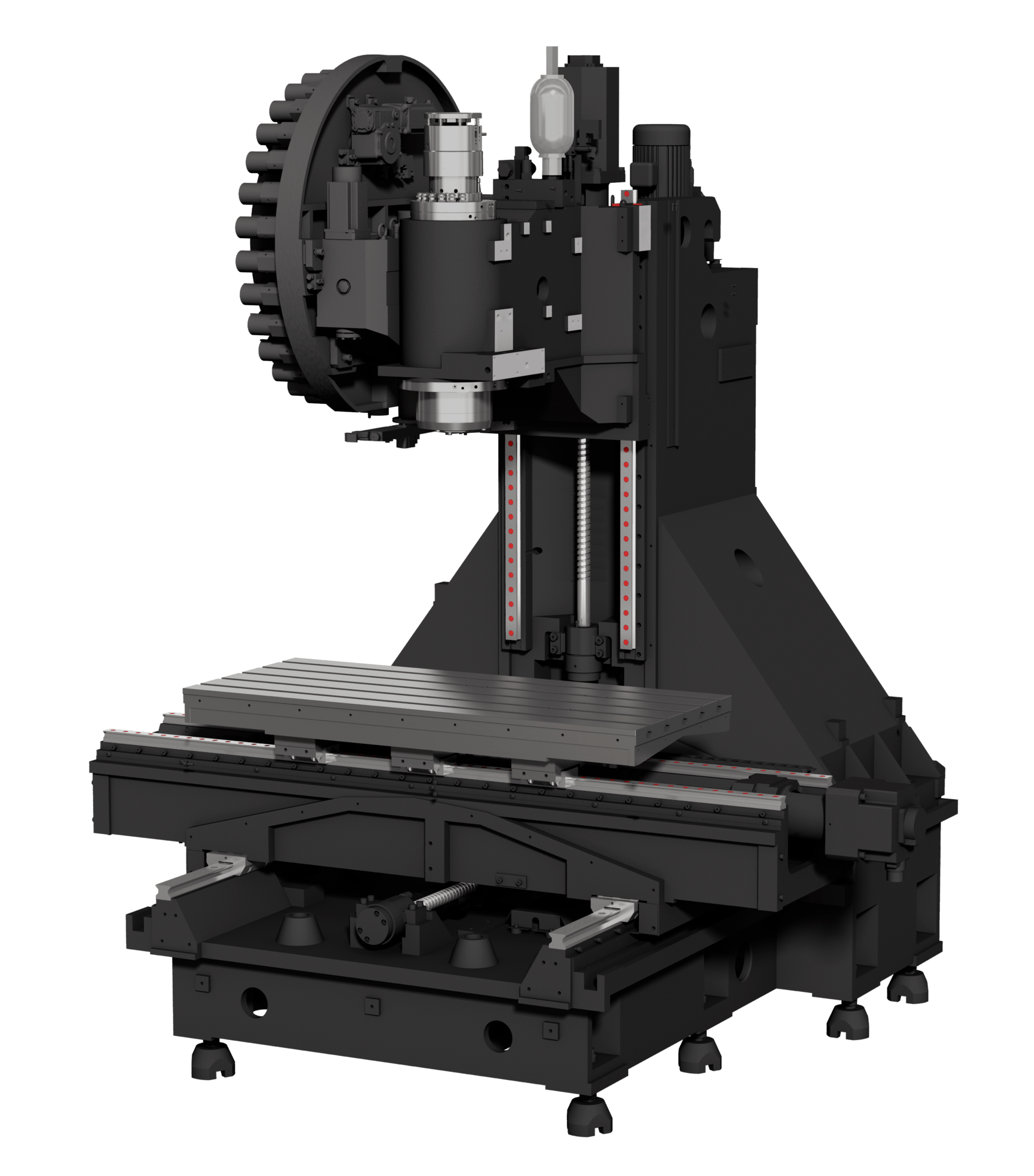

03 Servo tool changer stability improvement

The return-to-zero switch for new tool magazine arm ensures that the mechanical arm is effectively returned to its original position. Five-stage tool change in the tool magazine, with T-T up to 1.3s. Significantly reduce shock to the ATC and improve cam box life.

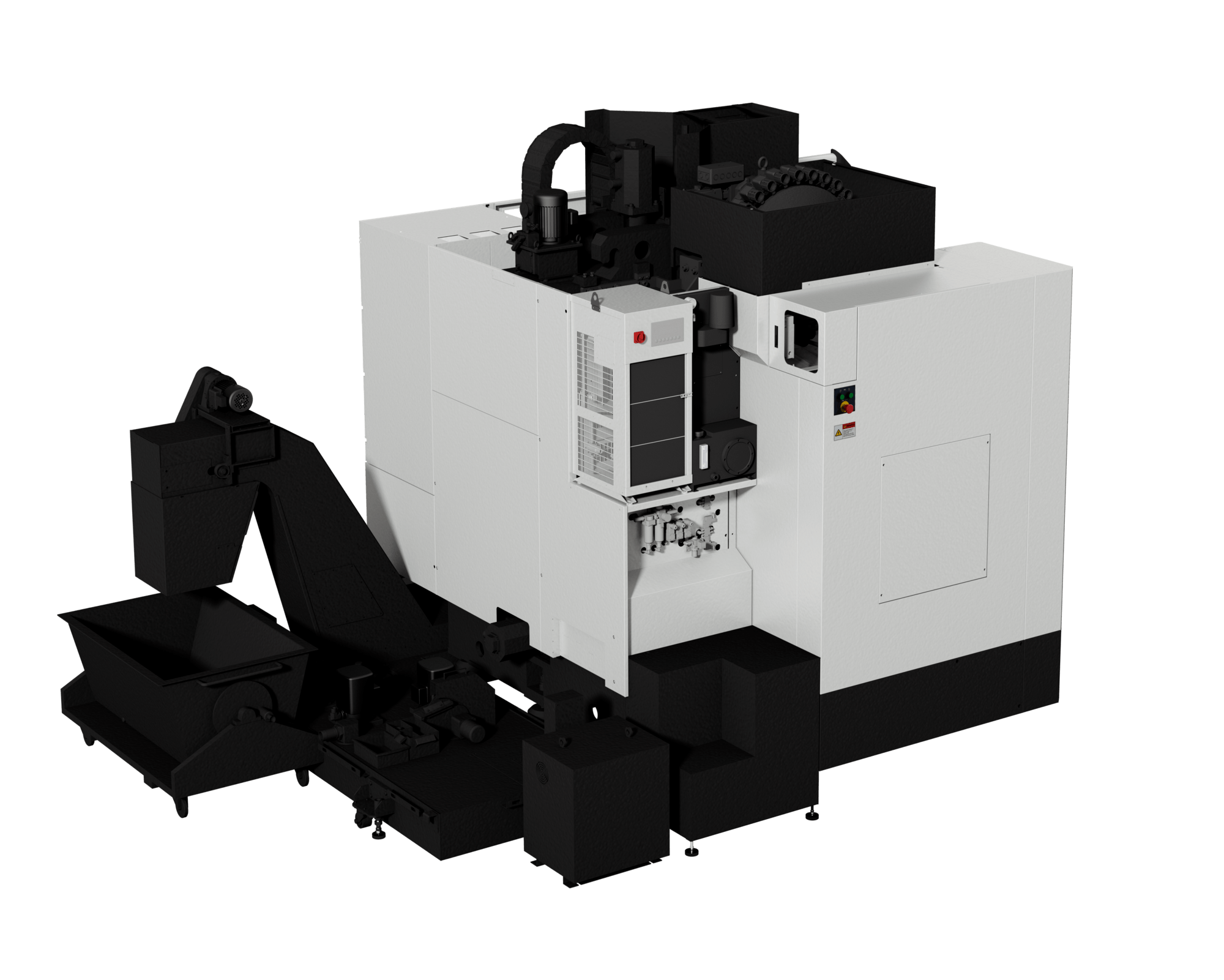

04 Newly designed functional layout of the whole machine

Each function module is open to the operator. With the standard maintenance foot pedal, it is more conducive to maintenance. With an integrated tank chip conveyor, it covers a smaller footprint.

Main parameters

Spindle speed (optional): 12000rpm (15000rpm)

Spindle power: 11/18.5kW

Spindle torque: 61.8/ 86.2N.m

Tool holder type (optional): BT40 (HSK-A63)

X\Y\Z axis travel: 1100\540\520mm

X\Y\Z axis swift moving speed: 48m/min

Worktable size: 1300×550mm

Tool magazine capacity (option): 24 (30T)