All machine tools can be protected by “guard”!

2020-09-09

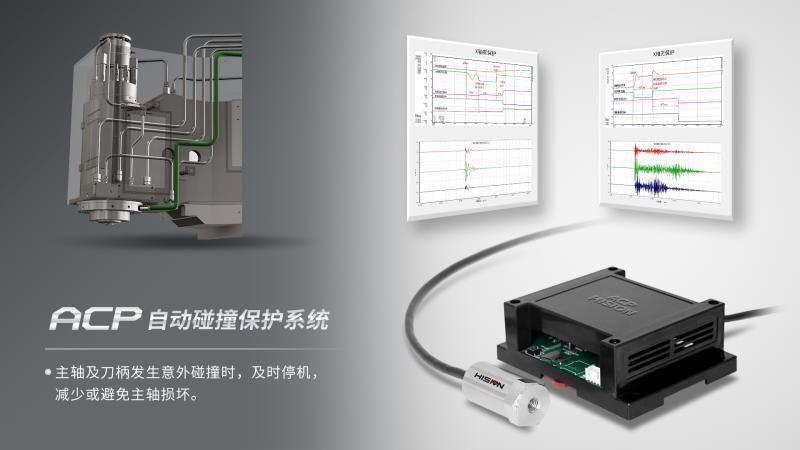

The machine tool collision will cause great damage to the accuracy of machine tool, especially for high-accuracy precision machine tool. Once accidental collision or overload occurs, the spindle might be easily damaged, so it is difficult to restore the original accuracy of the machine tool due to high repair cost. Therefore, machine tool collision must be eliminated absolutely. Anti-collision system can be used as the “machine tool guard”, which can effectively protect the machine tool from the damage caused by the collision.

Haitian Precision provides ACP automatic collision protection system for machine tool. The hardware is composed of 3D vibration sensor +PCB (made by Haitian), which can scan the acceleration signal of vibration sensor in a cycle of 1ms, monitor and record acceleration curve in real time, and trigger NC system of machine tool to alarm and stop when monitoring value exceeds alarm value during machining, so as to reduce or avoid damage of machine tool.

1.U disk can be used to read the health curve of the spindle (nearly one month) and the specific time of collision alarm can be queried. The history file is output in. DAT format, and the curve record is opened by EXCEL software for fault tracing.

2.PCB self-made embedded button battery (with long service life) is used to record the data when the machine tool is powered off, and keep the records from being lost.

3.The sensor monitors the acceleration value in the three-dimensional vector direction, and protects the spindle from impact from all directions.

The ACP automatic collision protection system made by Haitian Precision independently can prevent the spindle and handle of machine tool from being damaged due to impact or overload, lower the repair cost, reduce the processing quality problems and avoid production schedule delay. It is a reliable “guard” in the production and operation of machine tool and deserves your trust!