Customer Story: Leaps of Smart Home Industry

2025-01-21

Guangdong is one of China’s leading provinces in the home furnishing industry, known for its strong industrial foundation and high degree of industrial clustering. Nanxing Machinery Co.,Ltd. is a standout example in this thriving sector. Founded in 1996 and listed on the Shenzhen Stock Exchange in 2015, NANXING MACHINERY has its headquarters in Dongguan, Guangdong, along with two R&D centers and four manufacturing bases across China. Let’s explore the story of its Shaoguan facility and its partnership with Haitian Precision.

1. Trusted Brand & Capabilities

As the demand for furniture and woodworking machinery has grown, NANXING MACHINERY has built a comprehensive product portfolio. This includes CNC cutting machines, intelligent flexible edge banders, CNC drilling machines, smart packaging solutions, intelligent workstations, and full-factory smart production line solutions. To support this expansion, advanced production equipment and technology were essential. After extensive evaluations, Haitian Precision emerged as the clear choice, earning NANXING’s trust with its proven capabilities.

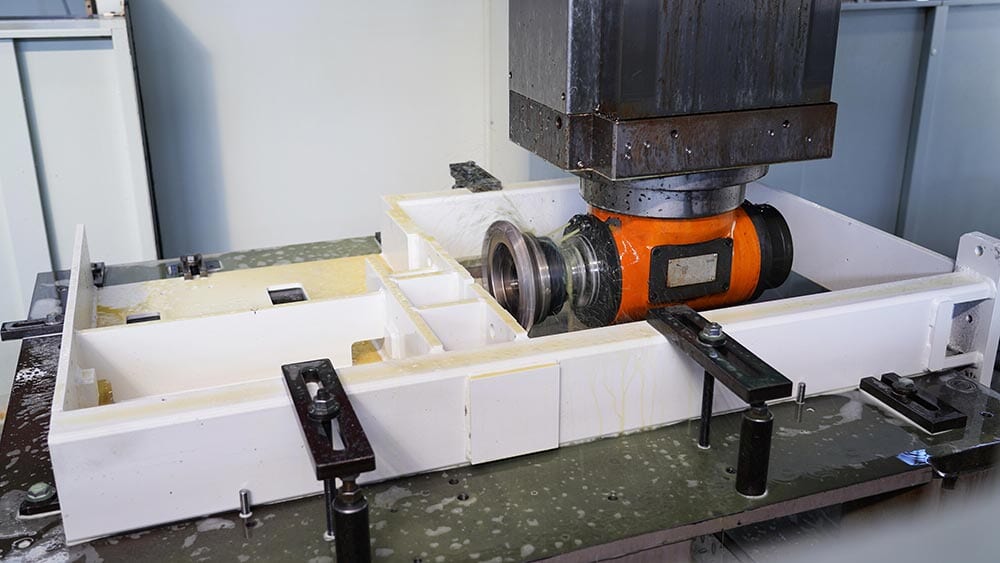

In 2021, the first Haitian Precision double column machining center was installed at NANXING’s Shaoguan facility. The entire process, from installation to full operation, took only three months. During installation, Haitian Precision’s professional service team conducted rigorous precision checks and shared detailed inspection reports with NANXING. This laid a solid foundation for the smooth operation of the machinery.

2. Quality & Efficiency in Harmony

With Haitian Precision equipment in operation, NANXING’s production efficiency experienced a significant leap. Processes that previously required two clamping and two shaping steps were streamlined into a single clamping and shaping process. Equipment utilization rates reached approximately 80%, doubling previous levels. Labor requirements were also significantly reduced. Haitian Precision’s machines come equipped with advanced tool magazines, smart operation systems, and real-time monitoring of parameters and energy consumption. This automation minimizes manual intervention, addressing challenges like low resource utilization and high labor costs. Today, one worker can oversee three machines simultaneously, ensuring efficient production management.

Impressed by these results, NANXING added three custom 20-meter gantry machining centers. These extended gantry systems allow simultaneous processing of four parts, reducing loading and unloading times and significantly boosting efficiency. “We spent over three years verifying it: Haitian Precision’s machining accuracy is absolutely reliable,” said Manager Wan.

3. Professional Service

Beyond its machines’ exceptional performance, Haitian Precision’s after-sales service is a key reason for NANXING’s long-term partnership. The service team is highly skilled and always resolves customer issues promptly. Whether it’s on-site precision inspections, practical recommendations, or customized solutions for special parts, Haitian Precision consistently delivers timely and effective support.

“Haitian Precision’s professionalism aligns perfectlywith NANXING’s commitment to its customers.”——Nanxing Machinery(Shaoguan) Co.,Ltd.Assistant to the Managing Director : Wan Jilang

Haitian Precision and NANXING MACHINERY share a commitment to market-driven strategies, user-centric thinking, and technological innovation. Together, they are advancing the home furnishing manufacturing industry towards greater sophistication, intelligence, branding, and sustainability. Looking ahead, Haitian Precision will continue to leverage its strengths, providing top-tier products and services to help home furnishing enterprises adapt to market changes, overcome challenges, and accelerate industry transformation and upgrading.